Robot cell Design

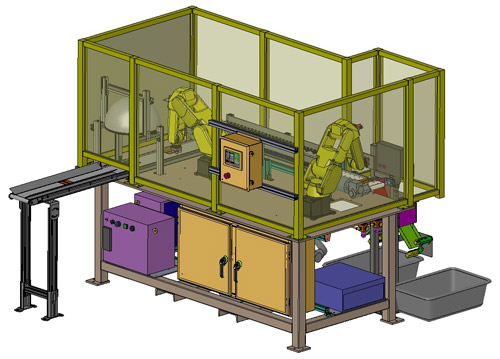

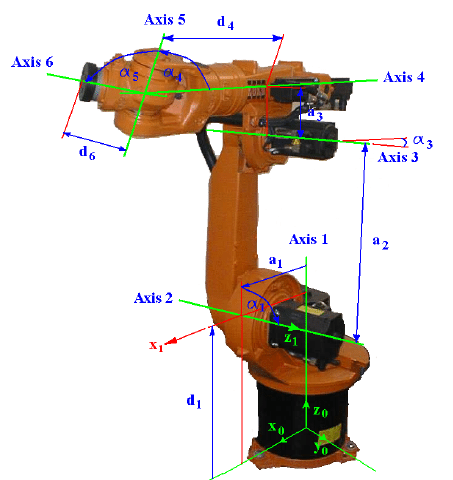

A robotic cell is a manufacturing cell in which loading and unloading operations are performed by robots. Three different cell layouts have been examined, namely:

⦁ robot-centred cells (where the robot movement is rotational),

⦁ in-line robotic cells (where the robot moves linearly), and

⦁ Mobile-robot cells (generalization of in-line robotic cells and robot-centred cells)

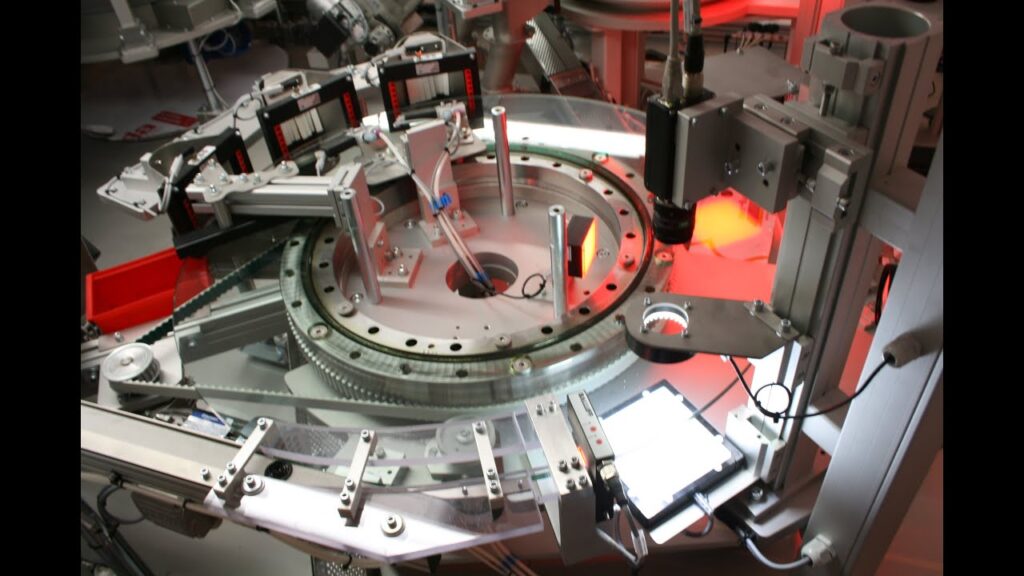

Robot-centred cell

Robot-centred cell is one of the commonly used layouts in the industrial applications. In this arrangement, a single robot will be incorporated at the centre of the work cell for performing operations on several machines that are set in a semi-circle form. This type of work cell is shown in the figure.

In-Line robot work cell:

An In-Line robot cell arrangement has a movable conveyor with the work parts. This conveyor travels near the robots for performing a function on the work parts. This type of arrangement is mostly used in the automobile industries for assembling the car bodies. To be more specific, the robots are placed beside the assembly line to carry out some operations like spot welding.

Mobile robot work cells

In the mobile robot work cells, the robots are arranged to move at different places in the cell. It is made possible by attaching the robot in a movable bottom, which is connected to the rail system.

This system can be done by either anyone of the following methods:

⦁ Overhead rail system

⦁ Floor track system

When comparing the floor track system and overhead rail systems, two things can be described:

⦁ The overhead rail system looks to be the best one in terms of floor space. The reason is that it requires less floor space than the floor track system.

⦁ The cost for constructing the floor track system is very lower than the overhead rail system.

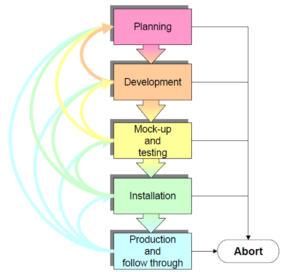

Design Sequence

The essential point to this chart is to plan for every eventuality, remembering that whatever can go wrong will go wrong.

Application

Isolation of the application requires a study of the current manufacturing operations to identify a suitable candidate for automation. It may become apparent at a later stage in the planning process that the chosen task should be disregarded in favour of another application, or that none of the tasks are suitable candidates for the introduction of a robot cell. Typical industrial applications of robots were discussed in previous lectures, many of which given fit into the following list:

-Spot welding

-Injection moulding

-Arc welding

-Machine loading

-Assembly

-Surface coating

-Handling and palletizing

-Press loading

-Grinding and deburring

-Die casting

-Inspection

-Gluing and sealing

-Casting, and

-Laser cutting.

Robotic Cell

Design and Supply Robotic cell

Robot simulation

Offline programming

Robot Installation and Integration

Onsite robot programming

Design services

Robot calibration among others

Robotics Solution

Automotive

Pharmaceutical

Material Handling and Assembly as Pick and place

Spot Welding Robotic Cell

Measurement

Sealants Application

Cutting with Laser and Plasma

Vision Integration and inspection system

Robotics Industry

Automotive Industry

Pharmaceutical

Heavy Engineering Industry