Why ICS cybersecurity?

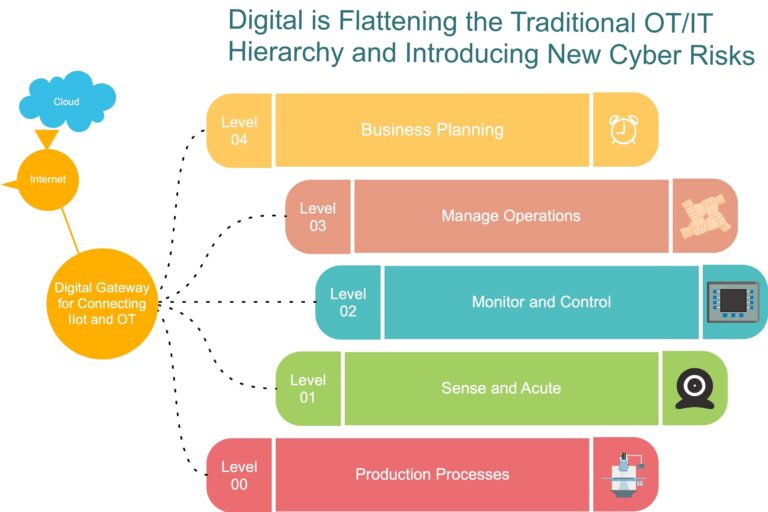

With emerging IT services, every aspect of the business is transforming into Digital Ready, so is the Industrial Operations. With emerging technologies such as Cloud Platform, IoT, Data Analytics, Machine Learning and Artificial Intelligence, it has become evident to connect, aggregate inputs, control operations of all the devices, machinery and tools present in the production cycle. With these changing business models, increased cost pressures and new regulatory requirements are accelerating the need for operational technology (OT) and information technology (IT) convergence. The Industrial Internet of Things (IIoT) enables unprecedented levels of real-time connectivity, visibility and control across core operations – while dramatically increasing cybersecurity risk.

Conventional security is not enough to protect against proliferating cyber threats to both OT and IT systems. Industrial control systems (ICS) on OT networks have different operational requirements that impact the ability to adapt and respond to new cybersecurity threats – and open up new avenues for cyberattack. ICS cybersecurity strategies are specifically designed with asset and operational requirements in mind to protect critical processes without negatively impacting efficiency, productivity and safety.

Industry 4.0

The Fourth Industrial Revolution (or Industry 4.0) is the ongoing automation of traditional manufacturing and industrial practices, using modern smart technology. Large-scale machine-to-machine communication (M2M) and the internet of things (IoT) are integrated for increased automation, improved communication and self-monitoring, and production of smart machines that can analyse and diagnose issues without the need for human intervention.

Design principles and goals

There are four design principles identified as integral to industry 4.0

⦁ Interconnection — the ability of machines, devices, sensors, and people to connect and communicate with each other via the Internet of things, or the internet of people (IoP)

⦁ Information transparency — the transparency afforded by Industry 4.0 technology provides operators with comprehensive information to inform decisions. Inter-connectivity allows operators to collect immense amounts of data and information from all points in the manufacturing process, identify key areas that can benefit from improvement to increase functionality

⦁ Technical assistance — the technological facility of systems to assist humans in decision-making and problem-solving, and the ability to help humans with difficult or unsafe tasks

⦁ Decentralized decisions — the ability of cyber physical systems to make decisions on their own and to perform their tasks as autonomously as possible. Only in the case of exceptions, interference, or conflicting goals, are tasks delegated to a higher level.

What We Do?

Ensure safe and secure operations by building and maintaining cyber resilience.

Prepare

We assess companies’ systems and processes to identify and address any gaps for vulnerabilities without negatively impacting safety or productively.

Prevent

We provide deep expertise and advanced security capabilities to deliver integrated security solutions across the ICS environment

Detect,respond & recover

Our proprietary tools and processes help companies identify , respond and recover from incidents quickly and effectively and minimize business impacts.

Who we work with?

Automotive & Industrial

Chemical

Consumer goods & services

High tech

Energy

Health